Case Study / Maintenance Dispatch

Building context/challenges.

Before implementing the maintenance management platform, the large-scale machinery and equipment at a certain petrochemical plant were primarily managed using methods such as telephone calls, paper-based records, and Excel spreadsheets for tasks like reporting malfunctions, troubleshooting, regular maintenance, and tracking processes. However, this approach often led to challenges in communication timeliness, difficulty in understanding repair statuses, and issues with the transfer of maintenance records.

Solutions

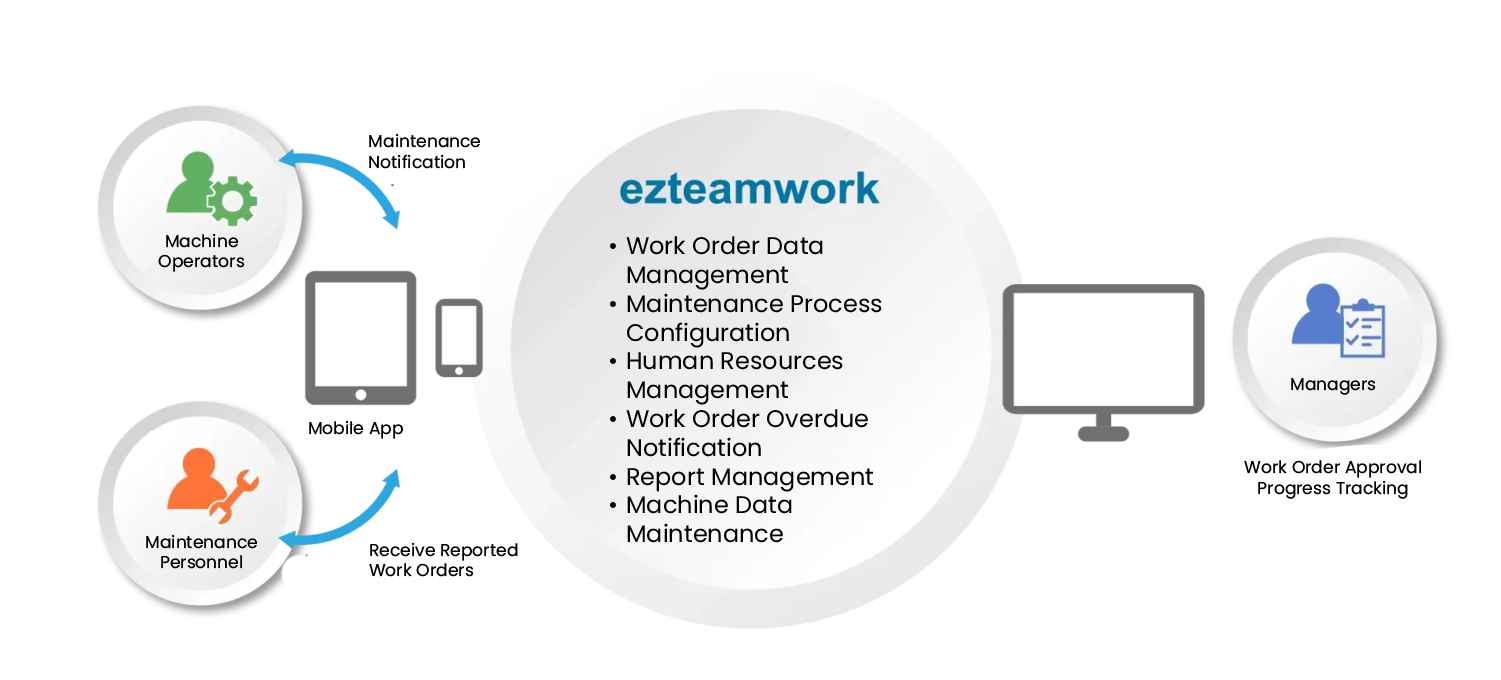

Using the system architecture of ezteamwork's maintenance management solution, the focus was on developing and implementing an equipment maintenance management system platform. Key aspects of the implementation included:

-

Repair personnel and maintenance staff can report fault situations and update repair statuses through the maintenance app, establishing a rapid mobile communication mechanism.

-

The maintenance app and backend data are synchronized bidirectionally, allowing management personnel to centrally review and manage real-time maintenance progress information for all machines.

-

Repair personnel can directly upload photos of machine faults on the maintenance app, allowing maintenance personnel to pre-assess the cause of the malfunction and accelerate operational efficiency.

-

The system can automatically remind based on the maintenance cycle of the equipment and generate maintenance orders for management to plan dispatch operations, simplifying the maintenance process.

-

The system platform can generate various statistical reports based on the latest data, helping management personnel to grasp the real-time maintenance status.

-

The system retains comprehensive maintenance records, facilitating effective big data analysis of machine failure rates and maintenance management performance.

Benefits of implementation.

- More timely and accurate monitoring of maintenance progress helps to increase productivity and reduce revenue losses caused by downtime.

- Streamlining the maintenance and servicing process enhances operational efficiency, reducing the time and cost associated with traditional communication methods.

- Utilizing technology to implement digital transformation, establishing a comprehensive and effective maintenance management mechanism, enhances productivity and shipping performance.

- Combining big data analysis for more accurate performance analysis, predictive maintenance, manpower, and inventory management.

- Centralized and comprehensive maintenance data recording facilitates the inheritance of maintenance and repair experience.

- Empower employees to continuously upgrade their skills and capabilities to keep pace with the times.

Company Introduction

A major petrochemical plant is a large-scale high-performance materials company based in Taiwan, also a leading supplier of international plastic and rubber materials, specializing in research and development as well as manufacturing various cutting-edge performance materials, serving clients worldwide.

Industry category.

Petrochemical Industry / Traditional Manufacturing Industry

Solutions

Equipment Maintenance

Related cases

ACMEPOINT Energy Services

Establishing vertical integration services for the operation and maintenance of the construction site.

CF Renewable Enrtgy Technology Co., LTD.

Solar farm project management digitalization.