Case Study / Other

Building context/challenges.

► Customer requirements

The rubber factory is collaborating with a US equipment manufacturer on a development project. The customer has requested that this new product be completed from specification confirmation to mass production within six months. In order to implement tasks such as product confirmation, personnel readiness, equipment readiness, procurement, and product mass production, the rubber factory has decided to adopt project management methodologies and software tools. Through the introduction of project management information systems, the company aims to strengthen its project management capabilities and improve communication with customers, suppliers, and internal stakeholders.

► Internal pressure

In addition to the demands from clients, for the rubber factory itself, the development of a product or the execution of a project often involves numerous personnel, considerable time, and substantial expenses, leading to the following challenges during implementation:

- Poor communication efficiency

- Lack of project planning concept

- Difficulties in generating performance reports

- Poor communication efficiency

- Lack of project planning concept

- Difficulties in generating performance reports

Solutions

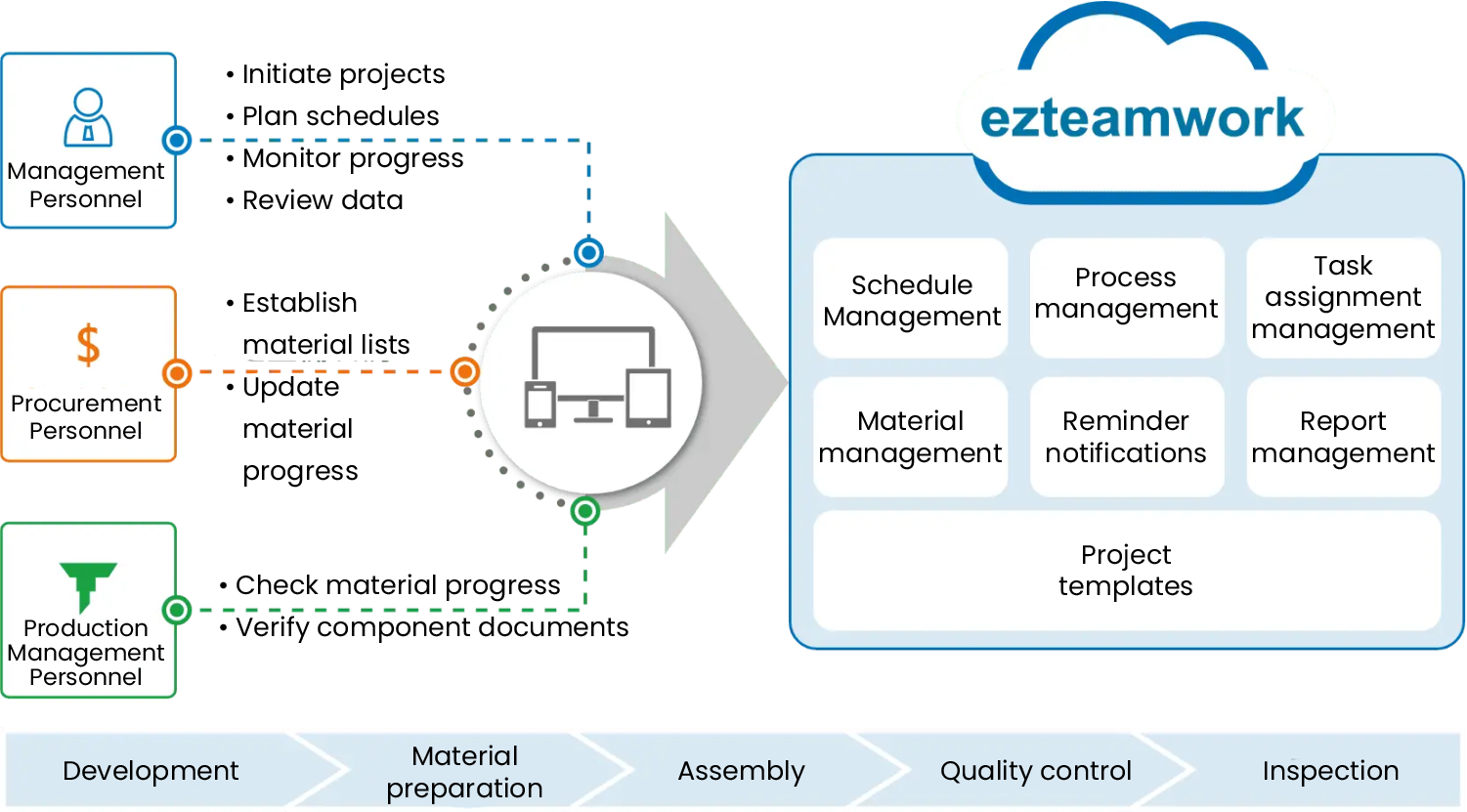

► Establishing an effective communication platform

Through the system's collaborative mechanism and support for multilingual functions, project members can gather on the platform for information dissemination, allowing members from different departments, regions, and even countries to synchronize their understanding of the project status.

► Manage resource allocation and monitor project progress.

The system assists project managers in scheduling projects and allocating resources, allowing for assignment and progress reporting within the system. Moreover, the system sends reminders for tasks falling behind schedule. All information regarding project progress and resource utilization is readily available on the platform, enabling real-time monitoring across time and location.

► Statistics charts and reports

The system provides a variety of statistical charts and reports, enabling quick generation of graphical information. It also integrates an Excel format export mechanism, facilitating project managers in conducting progress and performance analysis.

► Establishing a project workflow mechanism while preserving knowledge and experience.

Establishing a standardized project workflow mechanism through the system, and enabling quick replication of project structures using project templates to continue the standard workflow process. At the same time, the system can fully retain project information, assisting the company in building knowledge assets to serve as the basis for experience inheritance and reference for other projects.

► Establishing a document management system.

The system can centrally manage documents and integrate delivery outputs, versioning history, and audit processes. By digitizing the document management process, it can also link documents to work items for correspondence and reconciliation purposes.

Benefits of implementation.

- The system effectively reduces communication errors in project management.

- The project progress and status are clearly visible at a glance.

- Streamlining manual tasks to enhance work efficiency.

- Effectively preserving project knowledge assets.

- Enhancing competitiveness to international standards.

San Wu Rubber, established in 1946, specializes in the production of rubber conveyor belts and rubber power transmission belts, carrying the heavy responsibility of conveying various items and transferring power for a variety of machinery and equipment. Over the past seventy years, the company has upheld the spirit of "honesty, respect, responsibility, and innovation," striving to provide the best products and customer service.

Industry category.

Rubber products manufacturing industry

Solutions

Built-to-Order (BTO)

Related cases

Chengmao

Establishing a collaborative platform for managing a variety of small-scale orders.